Sustainability is a hot topic these days if judging by the growing number of inquiries our program office has been fielding this year. Customers want to know everything from our carbon emission reduction strategy to our labor policies to our reporting practices.

Of course, this is all in response to growing pressures that businesses are facing to account for their environmental and social impact. Amid rising awareness about the global challenges of climate change, fair labor practices, and social inequalities, today’s consumers are highly conscious about who they do business with. A growing body of research has thrown light on this class of conscious consumers, with one recent study finding that as many as 84 percent of global consumers consider sustainability important when choosing a brand. The influence of the conscious consumer is palpable no matter how you slice it: across every industry, customers are chiming with queries. So, in this post, I will share our answers to the most frequently asked questions in these five categories below, in no particular order:

- Flex sustainability program approach and methodology

- Greenhouse gas emissions

- Waste and water

- Other ways to reduce environmental impact

- Social sustainability

Flex sustainability program approach and methodology

How do we know you’re executing your sustainability program in ways that align to the highest standards?

We align with widely recognized frameworks that are of significant value to our business and stakeholders. These include: Global Reporting Initiative (GRI), Sustainability Accounting Standards Board (SASB), and UN Sustainable Development Goals (SDGs), among others. Over the last few years, our sustainability and reporting efforts have earned us the highest rating, Platinum, from EcoVadis, an improved DJSI score, and A in CDP – water security.

Consistent with our core value of doing the right thing always, we continue to set ambitious sustainability goals. For instance, we are committed to certifying all of our manufacturing sites as a Responsible Business Alliance (RBA) factory of choice by 2025. Certified factories demonstrate leadership through impact and transparency and are deemed compliant with the RBA Code of Conduct through external, biannual audits. As the RBA framework enables common standards and framework across the value chain, this helps customers gain greater confidence in their supply chain.

How do you approach the collection, validation, and reporting of your sustainability metrics?

Gathering and reporting data and aligning to widely adopted global frameworks is integral to a robust sustainability program. We have taken a programmatic approach to these activities for over a decade.

Since then, we have developed rigorous reporting and verification mechanisms that include the following:

- Each month, more than 80 Flex manufacturing facilities work with their Environment, Health and Safety (EHS) organization to collect and report their onsite environmental data. This site-specific data is then internally reviewed and validated by our sustainability team.

- We measure emissions from our non-production sites differently given their smaller environmental footprint.

- In addition to the monthly data review, we engage in additional internal data verification processes twice a year to ensure the utmost data accuracy ahead of our annual third-party audit. These activities prepare us for the development of our annual sustainability report, which is shared on our website.

Greenhouse gas emissions

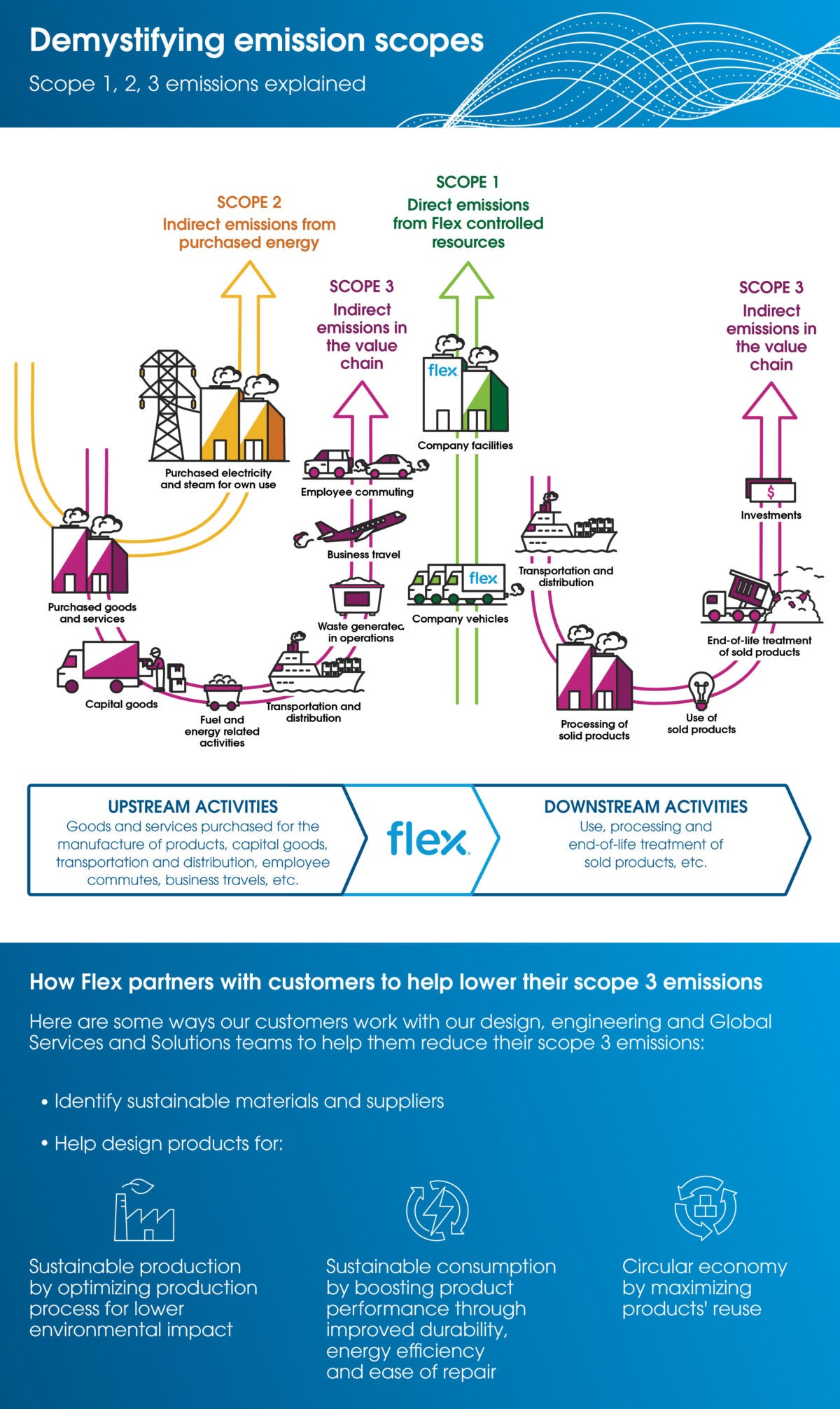

Can you, as my manufacturing partner, help me reduce certain categories of scope 3 emissions?

We can help our customers reduce certain categories* of scope 3 emissions through:

- Our circular economy solutions. We offer a broad range of circular economy services to help customers advance their sustainability commitments, including net zero. Identifying circular opportunities in production and material use/reuse can be a catalyst to curbing a product’s environmental impact and maximizing value recovery by extending the use of components, removing the need to produce new products, and optimizing more sustainable supply chains. For more information, please see our response to question 2 in the section “Other ways to reduce environmental impact.”

- Our net zero commitment and emissions reduction strategy. We announced a commitment to reach net-zero greenhouse gas (GHG) emissions by 2040. To support this goal, we will continue to take a multi-pronged emissions reduction approach that includes investing in site and system efficiencies, procuring and deploying renewable energy and continuing collaboration with our ecosystem of stakeholders to reduce emissions.

We are partnering with a segment of our customers and suppliers to help share and scale our learnings to help them on their sustainability journey and mitigate value chain emissions. We commit that 70% of our customers as measured by emissions covering purchased goods and services, capital goods, and use of sold products will set science-based targets by 2025 and 100% of our preferred suppliers will set greenhouse gas emissions targets by 2030.

*Categories include: Downstream transport and distribution, Processing of sold products, End-use of sold goods and services, Waste disposal and treatment of products, Downstream leased assets, Operation of franchises, Operation of investment

What is Flex’s roadmap to lowering its emissions?

Our 2030 operational emissions reduction strategy entails:

- Increasing energy efficiency

- Generating power on-site through renewable resources

- Purchasing renewable energy

While we are investing in these areas, we also understand there is no one-size-fits-all approach to achieving our sustainability targets at the country or even site level. This is because each country’s climate agenda reflects varying degrees of maturity. Hence, we are focused on identifying the right mix of the three initiatives across our diverse global footprint of more than 80 facilities.

How does Flex measure the emissions arising from the manufacture of my products?

To achieve economies of scale, we typically run multiple customer engagements at a single facility. As a result, we estimate each customers’ scope 1 and 2 emissions on request.

Customers increasingly request data related to the emissions associated with their product build. In response, we developed a methodology to estimate the emissions. We allocate scope 1 and 2 emissions based on Flex revenues generated by the production of the customer’s product(s).

Why did Flex join the Science Based Target initiative (SBTi)? How does this help me as a Flex customer?

Businesses can play a vital role in global decarbonization. Flex is committed to doing its part as sustainability is core to our vision to be the world’s most trusted manufacturing partner. By joining SBTi, we can reduce our carbon emissions aligned with climate science. As outlined in the Paris Agreement, global warming must not exceed 1.5°C above pre-industrial temperatures to limit the worst impacts of climate change.

Flex joined SBTi in 2021 to gain guidance on science-based targets including how much and how quickly we need to reduce our GHG emissions. As an independent third party that validates the targets proposed by businesses, SBTi works with more than 1,000 companies globally on their emission goals. We trust SBTi to use the most current science to help Flex align our strategies with the goals of the Paris Agreement.

Establishing science-based targets to reduce GHG emissions helps companies meet growing expectations from investors, customers, suppliers, employees, and other stakeholders to operate sustainably. We aim to cut our scope 1 and 2 emissions by 50 percent from 2019 levels by 2030 as a stepping stone to our long-term goal of reaching net zero by 2040.

Can Flex achieve an X percent reduction in its GHG emissions?

Some customers ask whether we can reduce our GHG emissions by a particular level. The overarching answer is we approach our emissions targets in a rigorous and purposeful manner backed by climate science. We outline our latest goals in our annual sustainability report which summarizes our targets, efforts, performance and results. This year, we set our most ambitious goals and aim to meet them by 2030. I encourage you to explore our 2021 sustainability report to learn more.

Waste and water

What is Flex doing to reduce waste?

We’re working toward a zero-waste to landfill future. To this end, we look to replicate the best practices of Flex sites that are zero-waste certified as we aim for at least half of our sites to meet this standard by 2025. In parallel, we will leverage our innovative reverse manufacturing and other circular economy techniques we have invested in over the years in support of our customers’ sustainability goals. This extends to helping customers design products that minimize environmental impact throughout their lifecycle. We are excited about our prospects in achieving zero waste across our sites as we mine our investment in circular economy practices.

What is your strategy for responsible water consumption?

Water is generally not a material input for products manufactured by Flex. Nonetheless, as we operate in markets challenged by water scarcity, we are proud to have signed the WBCSD Pledge for access to safe water, sanitation and hygiene (WASH). As a signatory of this pledge, we can help advance UN Sustainable Development Goal (SDG) #6 ensuring “clean water and sanitation for all.” In this, we commit to providing safe water, sanitation, and hygiene at the workplace for every employee in all premises within 2023.

Other ways to reduce environmental impact

How do you use carbon offsets as part of your emissions reduction strategy?

Given that we are members of the Science Based Targets initiative, the use of offsets cannot be applied to our emissions reduction strategy and commitments. The SBTi requires businesses to set targets based on emission reductions they directly influence through their value chain, which includes their own operations.

However, offsets can be a supplemental option for financing additional emission reductions beyond a company’s core, actionable strategy. For example, in 2020, we offset nearly 32,000 tonnes of scope 3 CO2e emissions through Certified Emission Reductions (CERs) Certificates from the Clean Development Mechanism from projects in Brazil, China, Costa Rica, India and the Philippines.

Can Flex offer a competitive solution to reduce my environmental impact?

Our Global Services and Solutions (GSS) team offers a broad range of integrated circular economy services, including repairs, refurbishment, and asset recovery, to help reduce your company’s environmental impact. As a member of the Ellen MacArthur Foundation and other research and development consortiums, we’re at the forefront of circular economy innovation, collaborating across industries to make sure you have access to the latest technologies and solutions.

Additionally, we have developed our own proprietary CO2 measurement and analytics focused on repair and refurbishment activities, to make informed decisions on how to reach environmental targets through measurable and achievable goals. We believe our continuing investments in specialists and specialized tools to measure the CO2 impact of circular economy services and the impact of logistics can help enhance your company’s approach to contributing to a circular economy.

Social sustainability

Where can I find Flex’s diversity and inclusion data?

We publish information about our global workforce annually in our sustainability report and 10-K, which includes the racial and ethnic representation of our US workforce. As exemplified by the appointment of Revathi Advaithi as Flex’s first female CEO, we are committed to diversity at all levels of the organization. As of September 2021, our 11-person board of directors included three female and six underrepresented minority directors. As we work towards our 2030 sustainability goals and evolve our human capital management disclosure, we will continue to provide updated information.

How can we partner with you on projects that benefit local communities?

While there are many ways to partner with us on community impact projects, a good starting point is to consider the project’s fit with our strategy. We are well-positioned to partner with you if your project benefits a community where Flex has a footprint. We can also create synergy if your project aligns to the community investment strategies of Flex and the Flex Foundation, our nonprofit charity arm.

Broadly, these strategies align to the UN Sustainable Development Goals (SDGs):

- #3 Good health and well-being

- #8 Decent work and economic growth

- #12 Responsible Consumption and Production

- #13 Climate action

Ways to partner:

- Together, we identify a project led by an international or local NGO that is aligned to one or more of the above SDGs.

- If you’re seeking funding for a project, we can help. The Flex Foundation awards grants to philanthropic initiatives supported by Flex. Grant proposals must meet a set of criteria and comply with various policies. Projects are then selected by the site community representative at a Flex location and the regional grant officers and approved by a grant review committee. To learn more about the Flex Foundation’s biannual grant cycles, please reach out to our sustainability team.

Here is an example of a community event in which we partnered with our customer Xylem: Flex improves access to clean water for communities in Mexico

Sustainability is one of the key pillars underlying our vision to become the world’s most trusted manufacturing partner.

As we make further inroads in our program, we look to instill greater confidence in our customers about our sustainability approach and execution.

With our ambitious sustainability targets through the decade, we look to deepen our commitment to creating long-term value that’s good for each other and our planet. As our journey evolves, we will update our responses as appropriate while continuing to share our experiences and learnings. If you need more, please email our sustainability program office.