My final post in this series on regionalized manufacturing will discuss how moving production closer to the customer can drive greater innovation, sustainability — and ultimately, great customer experiences.

Previously, I stated that the most valuable manufacturing partners offer an enabling platform across a global footprint that helps their OEM clients design, source, produce and support their products in ways that allow them to meet their customers’ ever-rising expectations. When we apply this platform across regions, OEMs can act with greater agility and unlock opportunities to deliver experiences that connect with their customers.

What consumers want

Superior customer experience is fundamental to winning in today’s marketplace, with about one in three consumers saying they would stop buying from a brand they love after just one bad experience.

What exactly does a good customer experience look like? Today’s consumers want not only great products but demand instant gratification and personalization. Fast shipping is not enough: they want a plug-and-play experience with their devices and appliances charged and configured on delivery. They want smart devices with customized apps that know their names and ready to learn their preferences. Aligning with your customers’ values is also critical considering that 80 percent of consumers cite sustainability as a reason for changing their purchase preferences.

No wonder brands are stepping up to provide speed, convenience, customization while engaging in sustainable practices. Case in point is a Flex consumer electronics OEM client that began a journey in 2018 to regionalize its manufacturing operations by bringing final assembly from Asia into its key regional markets. Under this model, each regional node in Asia, Europe and the Americas would assemble the finished goods based on actual demand, improving obsolescence rates and reducing inventory write-offs significantly. Postponing final assembly also cuts back on the rework required whenever inventory designed for one market needs to transfer to another nearby market to meet unexpected demand. Previously when shipping to Europe, for instance, multiple SKUs for a single product line were necessary due to the variances in electrical outlets in the region. Now the electrical plugs can be assembled with other components to fulfill a shipment.

Proximity to end markets not only helped the company’s regional markets better align their final production to demand signals, it also allowed them to create greater customization by loading the latest firmware into some of their products so they are ready to use on delivery.

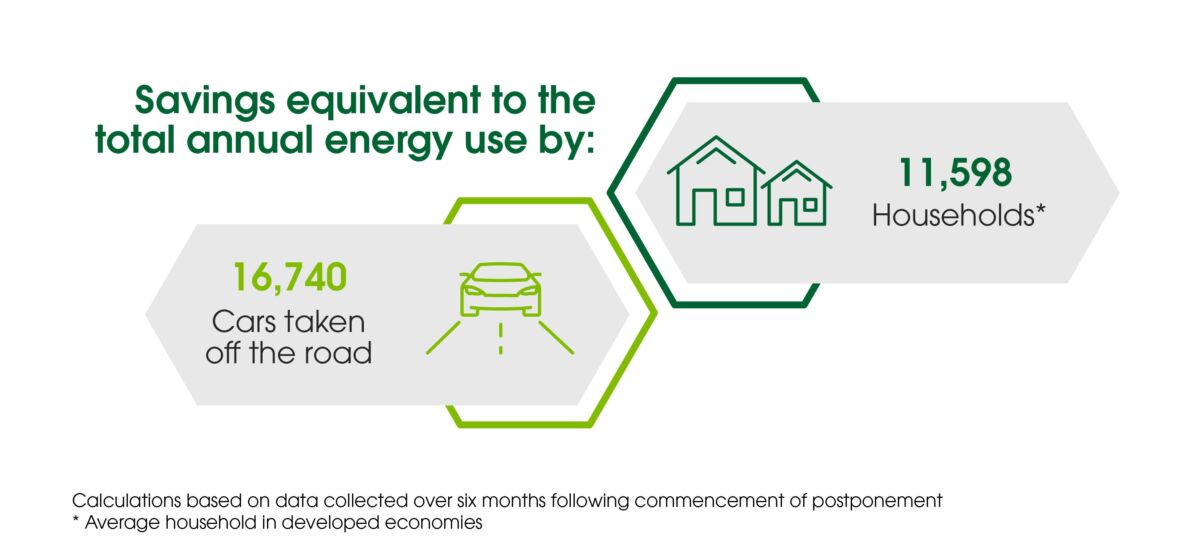

Whereas products previously shipped to the regions fully assembled in their final packaging, parts are now decoupled from the boxed packaging. Instead, the boxes are flattened for shipping, creating greater capacity to add more parts on each pallet thereby lowering each shipment’s environmental impact immediately in the first year (see graphic). With in-region final assembly, the OEM also shortened lead times while increasing inventory turnover.

Total annual CO2e impact associated with postponement shipments between China and Poland*

Shorter, more sustainable regional supply chains

Final assembly near end markets means a shorter supply network that not only reduces delivery risks but also the carbon footprint. This year, our OEM client is deepening its regionalization journey by developing local procurement networks. When both suppliers and customers are nearby, even less fuel will be required to transport parts and products; conversely, reverse logistics will also generate less carbon as parts don’t have to travel around the world to reach their place of manufacture and repair. Working with local suppliers also improves working capital thanks to shorter lead times. Finally, regional factories contribute to social sustainability, creating local jobs and bringing dollars into the community that are spent locally by employees.

To achieve greater environmental sustainability, we aspire to circular economy practices with nothing going to landfill; we believe regionalized manufacturing is the right model to unlock this opportunity. Our award-winning facility in Sorocaba, Brazil, has led the industry since 2012 by innovating on a closed loop supply chain. Integrating circular economy in all stages of the product lifecycle, Flex provides circular design services, enabling our clients’ products for sustainable manufacturing and circular end-of-life (EOL) strategies. At EOL, product parts are harvested to be used as inputs or spare parts in other products at our facility. In fact, Flex Sorocaba reuses or recycles 95 percent of the parts in EOL products; the rest are converted into energy with nothing entering landfill. Sorocaba’s circular economy practices led to its zero-waste certification in 2018, along with numerous awards over the years.

Proximity to customer can accelerate innovation

A manufacturer’s client-enabling platform must also include an arsenal of core technology building blocks that OEMs can access to develop innovative products.

In a world filled with smart, connected devices, OEMs need subsystems that provide a base architecture merging circuitry and components like WIFI chips and sensors. Once plugged into their environment, these units can be customized for wide-ranging applications by integrating hardware and software. An example of a core building block is a human machine interface (HMI) with displays, buttons and lighting that can be integrated into home appliances. Not only do these reference designs accelerate product development, they also speed production as they come pretested and ready to be configured and integrated in final assembly.

When you combine this foundational capability with in-region production, we can further innovate to fully tailor products in response to local tastes and regional trends. By operating close to the customer, we are well-positioned to understand consumer behavior along with all the varying personas. By leaning into how local consumers approach activities like shopping, cooking and cleaning, we can better translate their nuanced preferences into lifestyle appliances features and enhancements. For instance, when a government offers incentives for people to replace their legacy appliances with green-certified, energy-efficient ones, manufacturers can help their OEM clients anticipate and respond to expected behavioral shifts.

With production hubs established close to the end customer, we can open new doors to further delight the customer. This means instead of purely looking at what it costs to make and ship products, brands can engage their manufacturing partner to help drive customer satisfaction and loyalty across the entire product lifecycle.